Industries strive for sustainable innovation, but unstable materials and environmental concerns hinder progress. Non-ionic metamaterials offer a solution, enabling safe, durable, and eco-friendly product reinvention. EVOQ platform technology delivers these benefits through their metamaterial platform technology, empowering innovators in healthcare, textiles, energy, cosmetics, and beyond to create sustainable products. This post outlines seven key benefits of non-ionic metamaterials, showcasing how EVOQ drives impactful, sustainable outcomes across multiple verticals.

Non-ionic metamaterials eliminate risks, ensuring safety in sensitive applications. In healthcare, EVQ-218 kills pathogens without creating antimicrobial resistance, reducing infection risks in devices and improving patient outcomes. This safety supports sustainable product designs that prioritize user well-being without compromising performance, extending to oral care and other medical devices.

The metamaterial platform technology from EVOQ reduces costs by streamlining manufacturing with a scalable process. Production of the metamaterial is economical and fast, enabling innovators to reinvest in sustainable product lines. A textile brand, for example, used FUZE technology from EVOQ to scale antimicrobial fabric production, cutting costs and enhancing eco-friendly offerings for partners, including major global brands. A new product from FUZE made from a gold metamaterial called ExpeDRY was unveiled alongside Allied Feather + Down.

Stable, non-ionic metamaterials ensure durable performance, reducing replacement frequency. Traditional nanosilvers and other metamaterials degrade quickly and emit ions, creating agglomeration issues. Some manufacturers need surfactants and capping agents to delay degradation, but EVOQ metamaterials don’t have an oxidative layer and thus don’t require any extra chemicals to remain stable. This durability supports sustainability by extending product lifecycles, aligning with environmental goals across many industries.

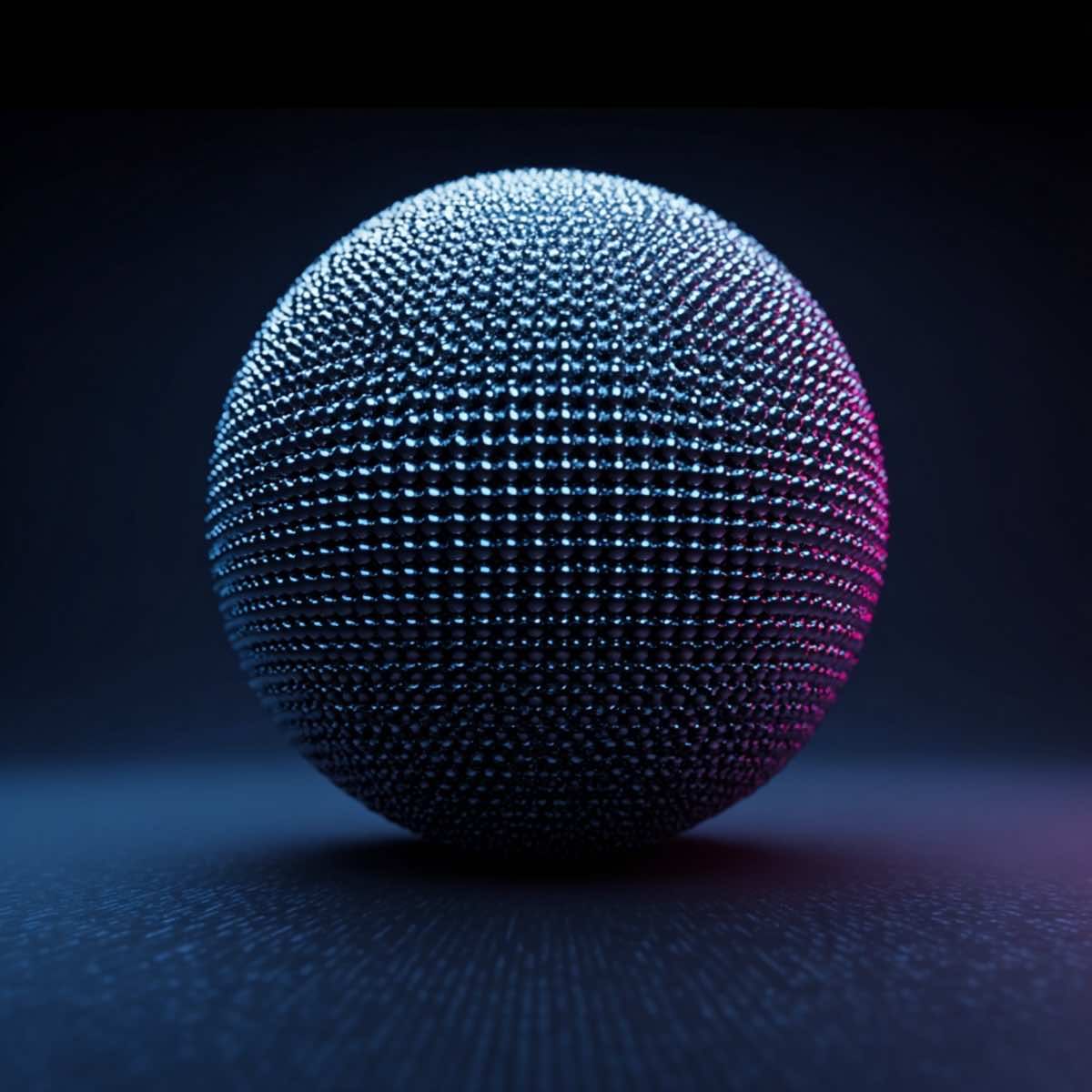

Consistent size distribution delivers precision for inventive designs. Consistently smooth sphere metamaterial enables accurate integration in new products, like medical devices. This precision empowers innovators to create reliable and performant solutions with consistent outcomes.

The cost-effective EVOQ processes scale seamlessly, supporting high-volume production. Simplified over many years, the high-energy laser ablation production process is extremely consistent and predictable. This predictability drives scalability and widespread adoption of eco-friendly innovations, from cosmetics to food packaging to energy storage.

Non-ionic, stable metamaterials meet stringent standards, simplifying approvals. In healthcare, EVQ-218 compliance with medical requirements accelerates market entry for new devices, reducing risks and costs. This supports sustainable innovation with fewer regulatory hurdles, benefiting numerous other industries as well.

The EVOQ platform technology produces inherently stable metamaterials, ensuring consistent performance across diverse applications. This unmatched stability and reliability empower innovators to transform industries like healthcare and energy with groundbreaking solutions.

EVOQ platform technology delivers non-ionic metamaterials that empower sustainable product innovations. With benefits like safety, cost savings, and stability, EVOQ metamaterial transforms industries while supporting environmental goals. Learn more about EVOQ sustainability impact to drive your next innovation.