For centuries, silver has been revered for its antimicrobial properties. From ancient civilizations using silver vessels to purify water to grandmothers placing silver coins in milk bottles to prevent spoilage, generations have long recognized silver's protective powers. Yet despite this rich history, modern medicine has struggled to harness silver's full potential—until now.

In a scientific advancement that could transform healthcare and numerous other industries, EVOQ has developed what the American Chemical Society journal has officially classified as "a new form of silver." This isn't just another incremental advance in metamaterial science; it represents a fundamental shift in our ability to combat one of healthcare's most pressing challenges: resistance to antimicrobials.

The silent pandemic you haven't heard enough about

While the world has become all too familiar with viral pandemics, another crisis has been quietly building for decades: antimicrobial resistance (AMR). The World Health Organization has designated AMR as one of the top 10 global public health threats. As bacteria evolve to outsmart our strongest antibiotics, we're entering what some experts call a "post-antibiotic era," where even routine infections could once again become deadly.

In hospitals, this threat is particularly acute. Every year, more than one million Americans develop healthcare-associated infections (HAIs), many from the very devices, such as ventilators and catheters, inserted to help them heal. Up to one-third of catheter-associated infections, for example, now show resistance to standard treatments, with annual costs exceeding $13 billion.

The problem with traditional silver metamaterials

Conventional silver metamaterials have shown promise as an antimicrobial solution, but they've been plagued by critical limitations that have prevented widespread adoption in healthcare:

- Ion emissions—Traditional silver metamaterials release ions that, while effective against bacteria, can also be toxic to human cells.

- Instability—Most silvers degrade within weeks, making them impractical for long-term use.

- Inconsistent size and shape—Variations make dosing unpredictable and effectiveness inconsistent.

- Manufacturing limitations—Traditional manufacturing approaches rely on chemical additives that can be problematic for medical applications.

Perhaps most concerning, the way conventional silver metamaterials kill bacteria—by rupturing cell walls—actually triggers pathways that can contribute to antimicrobial resistance, potentially making our AMR crisis worse.

A scientific advancement: EVQ-218

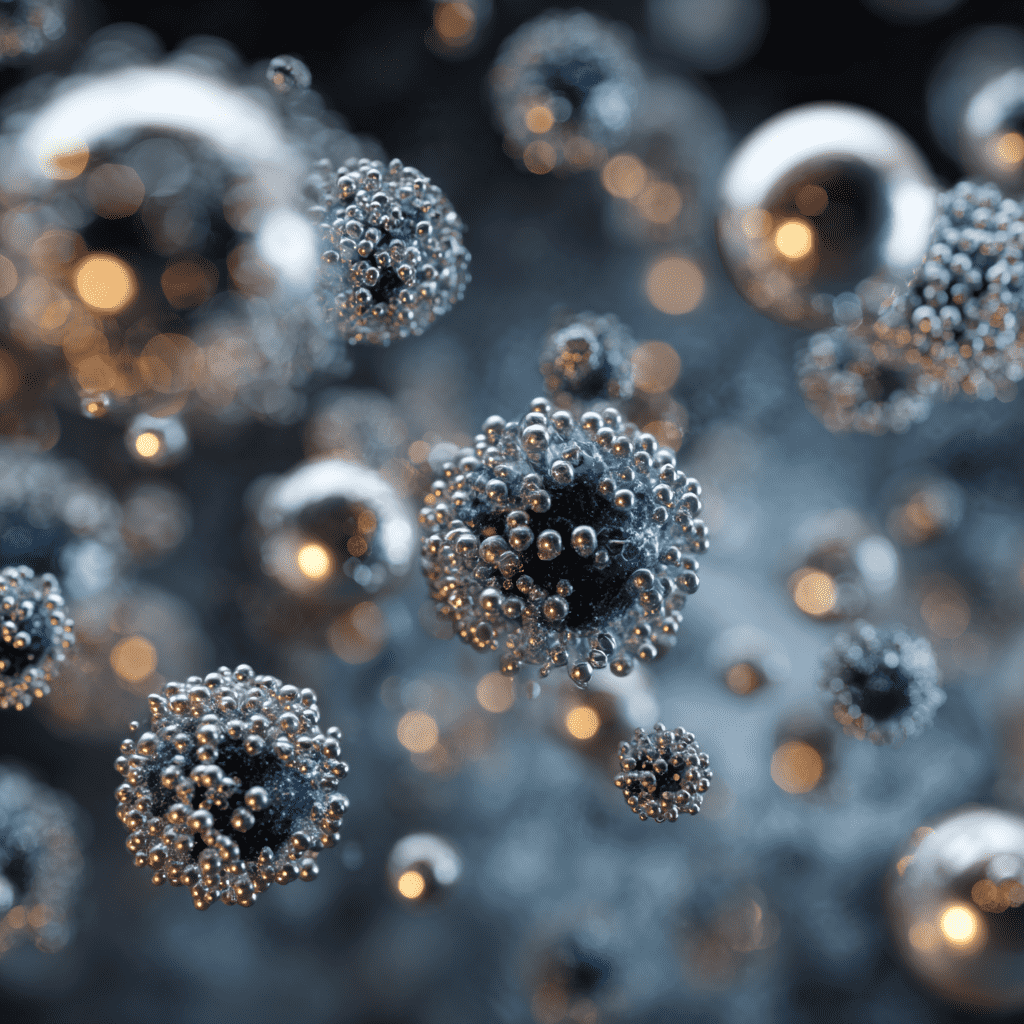

New discoveries in the metamaterial space offer new hope. In a peer-reviewed study published in ACS Omega, scientists characterized EVQ-218, a novel metamaterial developed by EVOQ, as a fundamentally new form of silver metamaterial—one that overcomes all the traditional limitations.

"Not only does EVQ-218 match the National Institute of Standards and Technology's (NIST) standards for particle size and shape, but it possesses an ultra-stable shell structure that completely inhibits ion emission. This is a first for a pure metal metamaterial," explains Shaun Rothwell, CEO at EVOQ.

This distinction matters tremendously. EVQ-218 is the first stable, non-ionic metamaterial ever developed. Unlike conventional silvers that emit harmful ions, these smooth, uniform-sized metamaterials maintain their integrity without degradation.

In practical terms, this means EVQ-218 stays stable over time, unlike traditional silvers that break down within weeks. The metamaterials are consistently under 10 nanometers in size and shape and meet the gold standard set by NIST. EVQ-218 doesn’t require chemical stabilizers, making it a clean, environmentally friendly option. And unlike other solutions, it fights bacteria without adding to the problem of antimicrobial resistance.

The science behind EVQ-218

EVQ-218's distinctive properties stem from how it’s created. Unlike conventional methods that rely on chemical synthesis, this metamaterial fabrication process uses only laser energy, ultrapure water, and pure silver metal, which represents a significant advancement in the field.

The metamaterial fabrication process operates at temperatures and pressures similar to diamond formation, generating ultra-stable metamaterials through a multi-laser ablation system. This approach enables consistent, high-volume production while eliminating the chemical residues associated with traditional methods.

"Our manufacturing process creates a fundamentally different material," adds Rothwell. "By avoiding chemical synthesis entirely, we've developed environmentally safe metamaterials that are not only more effective but also more sustainable to produce."

How it works: A novel mechanism of action

Perhaps most remarkable is how EVQ-218 fights bacteria. Unlike conventional antimicrobials that damage bacterial cell walls and trigger warning signals to adjacent bacteria, these metamaterials employ a completely different approach:

- EVQ-218 stops bacterial growth by shutting down bacteria’s energy source.

- This inhibits metabolic activity within the bacterial cell without compromising cell structures.

- Since EVQ-218 doesn't break the cell wall, it avoids activating bacterial mutations that contribute to resistance.

Think of it like shutting down a factory's power supply instead of demolishing the building. By targeting the bacteria's energy source rather than destroying its structure, EVQ-218 eliminates the microbe without triggering the alarm systems that lead to resistance.

Real-world applications: Beyond theory

While scientific advancements often remain confined to laboratories, EVOQ is translating this discovery into practical applications. By incorporating EVQ-218 into medical device manufacturing, the technology enables a new generation of infection-resistant products. The technology can be integrated in multiple ways:

- During raw material synthesis.

- Incorporated into polymer pellets.

- Applied to finished devices post-production.

- Added to surface modification coatings.

Beyond medical devices, the applications span diverse industries. In healthcare, the technology could enhance surgical instruments, implants, and wound dressings with lasting protection. Consumer products would benefit from durable antimicrobial surfaces, while the energy sector could use these metamaterials to create longer-lasting, more efficient batteries.

What separates metamaterial science's potential from real-world impact is scale. Many metamaterials show remarkable properties in the lab but fail to reach commercial applications because they can't be produced consistently and cost-effectively.

The metamaterial platform from EVOQ addresses this critical barrier. By enabling high-volume production of stable, uniform metamaterials, the technology bridges the gap between theoretical potential and practical application.

A more promising future

As antimicrobial resistance continues to rise, EVQ-218 offers something we desperately need: a new approach that bacteria haven't seen before and can't easily overcome. As this technology moves from the laboratory to hospitals worldwide, it could help preserve our dwindling antibiotic resources while providing new tools to fight increasingly resistant infections.

The silver that generations have valued for millennia is entering a new era—one where its power is harnessed not just through tradition, but through cutting-edge science that's revealing properties we never knew existed. From medicine to energy storage, textiles to consumer products, this redefinition of a familiar element demonstrates how metamaterial innovations can solve some of today's most persistent challenges, opening doors to possibilities we're only beginning to explore.