Each year, more than a million patients in U.S. hospitals develop healthcare-associated infections (HAIs). These are not infections they arrive with, but ones they acquire during their hospital stay. Often, they’re caused by the very tools meant to support recovery — catheters, IV lines, implants, and surgical devices.

Despite efforts across the healthcare system to prevent HAIs through hygiene protocols and antibiotic use, infection rates remain a stubborn challenge. These infections prolong hospital stays, increase readmissions, and in many cases, lead to serious complications or death. The cost is staggering, with an estimated 10 billion dollars added to the healthcare system annually.

At EVOQ, we believe there’s a better way forward by starting at the source of the problem. What if medical devices could be designed not only to perform their intended function but also to actively reduce the risk of infection? That question has been at the heart of our work, and today we are closer than ever to answering it.

Rethinking how we prevent infections

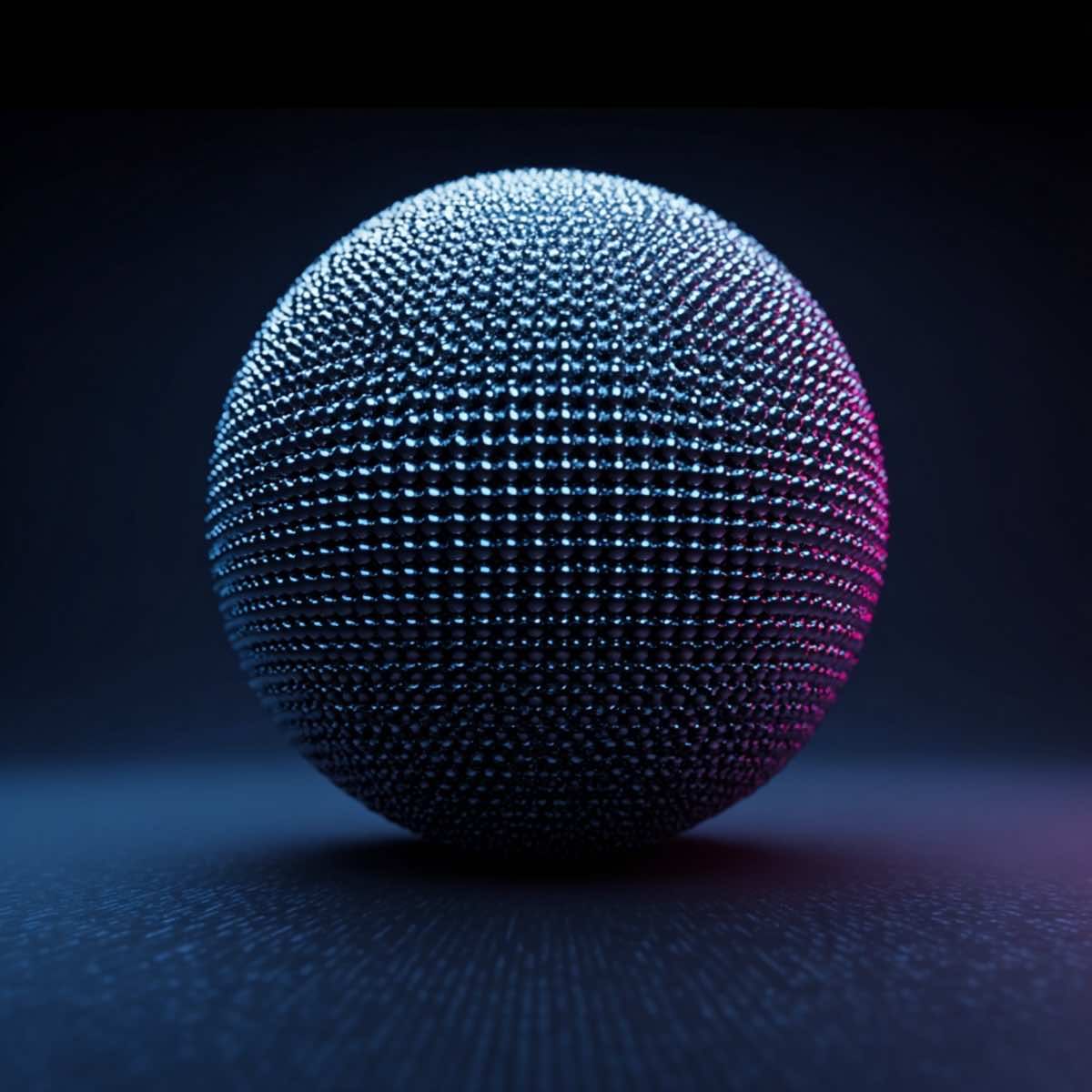

Using a proprietary fabrication process, we’ve engineered a novel metamaterial called EVQ-218. It represents a new approach to medical device safety, one that goes beyond coatings or temporary barriers. EVQ-218 can be embedded into medical devices at multiple stages of manufacturing, making it a flexible solution that fits into existing production workflows without compromising the performance or structure of the device.

This adaptability is critical. We have demonstrated success with four primary integration methods:

- During synthesis of raw materials

- Incorporated into polymer pellets

- Applied post-production to finished devices

- Added as part of a surface coating

Each method has shown strong antimicrobial efficacy across a range of real-world medical device applications, including catheters, luers, fittings, and coatings.

A new kind of silver

Silver has long been used in healthcare for its antimicrobial properties. But traditional silver particles tend to work by rupturing bacterial cell membranes, which can damage surrounding healthy tissue and trigger antimicrobial resistance. That mechanism, while effective in the short term, can carry long-term consequences.

EVQ-218 works differently. It is the first stable, non-ionic silver metamaterial that kills bacteria from the inside, rather than breaking the cell wall. This approach reduces the risk of triggering resistance pathways and avoids the cytotoxicity concerns that have plagued conventional silver-based solutions.

This distinction has been recognized by the scientific community, with ACS Omega, a publication of the American Chemical Society, classifying EVQ-218 as a new form of silver. The findings highlight not only the safety profile of EVQ-218 but also its potential to unlock broader therapeutic use of silver in ways previously thought to be unattainable.

Proven results without compromising performance

In our extensive laboratory testing, EVQ-218 consistently demonstrated a greater than 99.99+ percent reduction in leading pathogens associated with healthcare-associated infections. Just as important, the materials retained their original strength, flexibility, and function. Medical devices treated or produced with EVQ-218 continue to meet the high-performance standards required in clinical environments.

This is especially important for medical device manufacturers. Too often, antimicrobial additives interfere with the physical properties of the final product. With EVQ-218, those trade-offs are eliminated. Our technology enhances safety without altering the design or function of the device itself.

Moving from treatment to prevention

At EVOQ, we see antimicrobial resistance not as a future threat, but as a current reality. Drug-resistant infections are increasing, and the pace of new antibiotic development is falling behind. That’s why the most effective path forward includes not only new therapies but also smarter prevention strategies.

Our approach focuses on making infection prevention intrinsic to the device itself. This reduces the need for systemic antibiotics, limits exposure to resistant strains, and protects both patients and healthcare providers.

We also understand that change in healthcare must be realistic. Solutions must work with existing systems, not against them. That is why we designed EVQ-218 to be integrated into multiple stages of production. Whether it’s during raw material development or final surface finishing, EVQ-218 can be added without disruption.

A safer future for patients and providers

The real-world impact of EVQ-218 goes beyond the lab. It means a reduced risk of infection for patients recovering from surgery or living with implanted medical devices. It means peace of mind for providers who know that the tools they use are contributing to better outcomes. And it offers a cost-effective solution for hospitals and manufactures working to meet stricter safety and regulatory standards.

Innovation does not always require a complete reinvention. Sometimes it means improving the materials we already trust. By advancing how we integrate antimicrobial protection into devices, we are contributing to a safer, more resilient healthcare system.

What comes next

We continue to work with partners in the medical device industry to bring EVQ-218 into broader clinical use. Like all medical advancements, widespread adoption takes time, collaboration, and rigorous validation. But we are confident in the foundation we have built and encouraged by the results we are seeing.

Our team at EVOQ is committed to creating technologies that redefine what is possible. We believe medical devices should not only support healing but actively protect against harm. EVQ-218 brings that vision closer to reality.